At Fluid Focus, precision and performance are at the heart of everything we do. Our San Marcos, California facility is fully equipped to handle every aspect of modern suspension service, testing, and development — all under one roof.

Our shop is home to a team of highly experienced suspension technicians who bring years of hands-on experience from both the mountain bike and motorsports industries. Each tech is dedicated to delivering the highest level of customer service, craftsmanship, and ensuring every fork and shock that leaves our doors performs at its best. With our in-house engineer and machinist, we’re able to develop, test, and refine products quickly — keeping innovation and performance aligned with the needs of modern riders.

We’ve invested heavily in state-of-the-art equipment and in-house capabilities. Our machine shop features a Haas VF2SS, Haas ST10, Bridgeport mill, and Hardinge lathe, allowing us to manufacture small batch production runs, prototype new designs, and maintain full control over quality and tolerances.

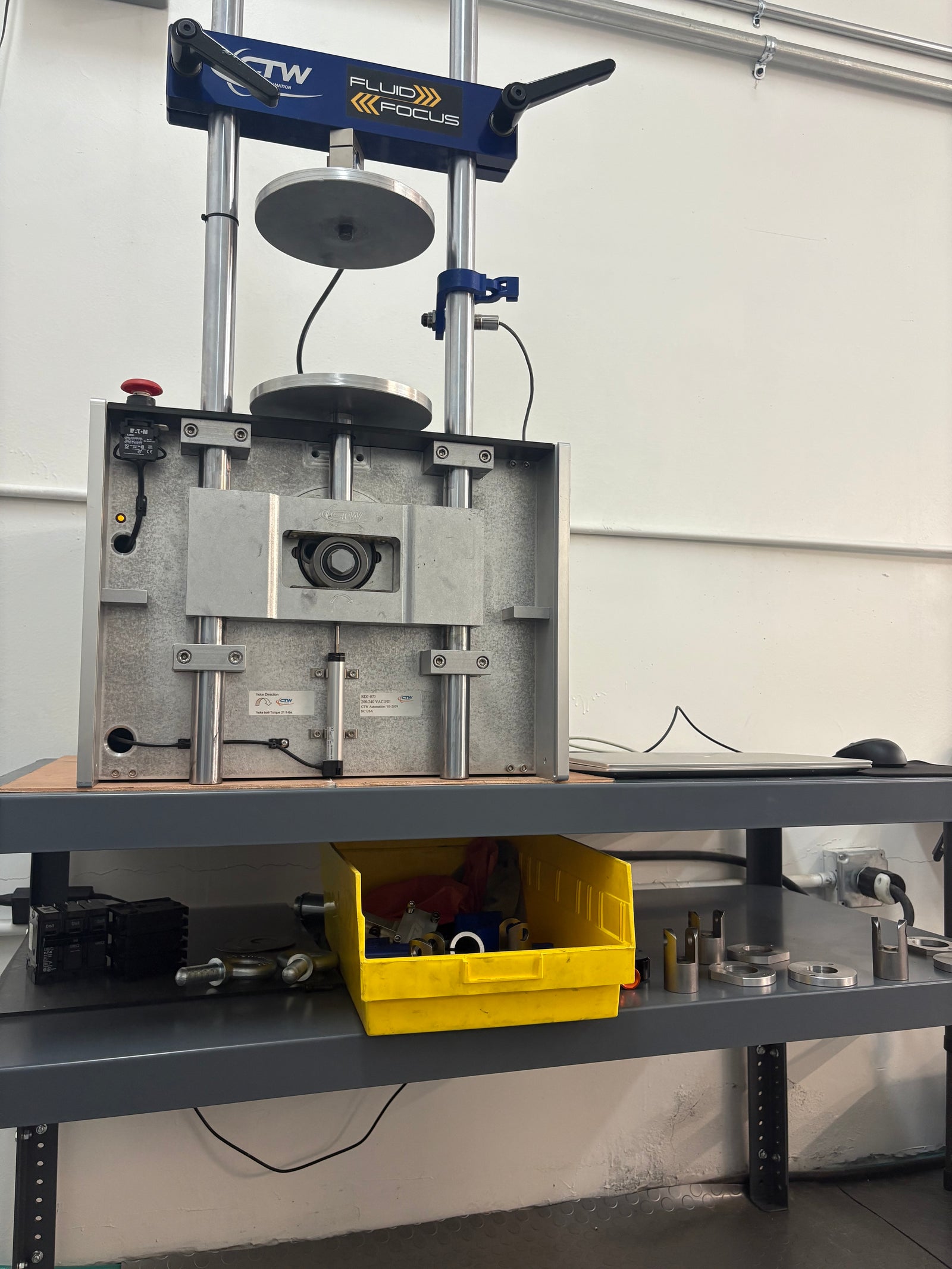

To support our data driven approach we utilize advanced testing tools including a CTW Linear Actuator dyno and CTW crank dyno. Utilizing BYB Telemetry adds another layer of insight when developing custom tunes, giving us the ability to fine-tune settings in real-world conditions.

SAR (Super Alloy Racing) is our in-house spring brand. Springs are designed and manufactured in collaboration with Eibach to the same demanding standards we apply to every Fluid Focus project. Having control over the exact spring rate ensures proper bike balance and damper optimization.

We don’t just tune suspension — we integrate our own products directly into every custom setup. By designing and developing components in-house, we give our team the tools to push performance boundaries, enabling suspension that responds precisely to the demands of riders. Every product we create is designed to improve adjustability, consistency, and overall ride quality, ensuring that every bike leaves our shop dialed to perfection.

Whether it’s a full custom tune, prototype development, or precision service, the Fluid Focus shop is built to deliver industry-leading results backed by real engineering, real testing, and real experience.

At Fluid Focus, precision and performance are at the heart of everything we do. Our San Marcos, California facility is fully equipped to handle every aspect of modern suspension service, testing, and development — all under one roof.

Our shop is home to a team of highly experienced suspension technicians who bring years of hands-on experience from both the mountain bike and motorsports industries. Each tech is dedicated to delivering the highest level of customer service, craftsmanship, and ensuring every fork and shock that leaves our doors performs at its best. With our in-house engineer and machinist, we’re able to develop, test, and refine products quickly — keeping innovation and performance aligned with the needs of modern riders.

We’ve invested heavily in state-of-the-art equipment and in-house capabilities. Our machine shop features a Haas VF2SS, Haas ST10, Bridgeport mill, and Hardinge lathe, allowing us to manufacture small batch production runs, prototype new designs, and maintain full control over quality and tolerances.

To support our data driven approach we utilize advanced testing tools including a CTW Linear Actuator dyno and CTW crank dyno. Utilizing BYB Telemetry adds another layer of insight when developing custom tunes, giving us the ability to fine-tune settings in real-world conditions.

SAR (Super Alloy Racing) is our in-house spring brand. Springs are designed and manufactured in collaboration with Eibach to the same demanding standards we apply to every Fluid Focus project. Having control over the exact spring rate ensures proper bike balance and damper optimization.

We don’t just tune suspension — we integrate our own products directly into every custom setup. By designing and developing components in-house, we give our team the tools to push performance boundaries, enabling suspension that responds precisely to the demands of riders. Every product we create is designed to improve adjustability, consistency, and overall ride quality, ensuring that every bike leaves our shop dialed to perfection.

Whether it’s a full custom tune, prototype development, or precision service, the Fluid Focus shop is built to deliver industry-leading results backed by real engineering, real testing, and real experience.